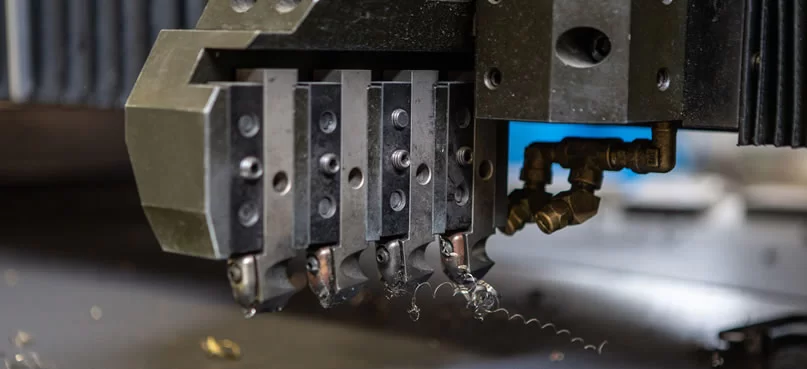

Introduction to the use of cutting grooving blades

Turning tools and applications Turning tools are the most widely used single-edged tool. It is also the basis for learning and analyzing various types of tools. Turning tools are used in all kinds of ...

2019-11-28-

Carbide non-standard tool

T-slot milling cutter, "Carbide non-standard tool": It uses high-speed steel and hard alloy to process general easy-cutting metal (HRC30 or below), and can be made of high-speed steel....

28-11-2019 -

Metal cutting technology and tool development status

Since the mid-20th century, due to the fruitful achievements of science and technology such as microelectronics, information technology, and materials science, and the acceleration of engineering progress, the rapid development of manufacturing and manufacturing technology has been promoted. By the ...

28-11-2019 -

Using ESC technology to improve the durability of cemented carbide thread blades

The ESC (Edge and Surface conditioning) process is a process for the enhancement (passivation) and surface polishing of the cutting edge. Through the ESC process, the tool edge strength can be enhanced, the surface stress state is improved, the surface roughness value is reduced, and the tool durabi...

28-11-2019 -

Application of cutting graphics for oil pipe thread blades

How to design the cutting figure of each tooth structure and the distribution of the cutting load of each tooth is very important for improving and progressing the quality, efficiency and tool life of the screw thread. ...

28-11-2019 -

Twin Tooth thread Blades

The latest development of threaded cutting technology is a blade with a special geometrical shape (two teeth with different contours). This combination allows the number of strokes to form a complete thread to be reduced by as much as 40% compared to a single tooth tool, while also increasing the to...

28-11-2019 -

The use of three-sided edge milling cutter

In addition to the main cutting edge of the circular surface, the three side milling cutter has the side cutting edge, which improves the cutting condition, improves the cutting efficiency and reduces the surface roughness. ...

28-11-2019 -

Enlargement of milling range of three-sided edge

The high mountain cutters have added two new types of three-sided milling cutters to the most comprehensive range on the market. With 335.19 milling cutters and SNHQ blades, you have a perfect combination; the tool lives longer, has better surface quality, and also benefits the machine....

28-11-2019 -

method of coarse milling of large modulus gear teeth with three-sided edge milling cutter

It is suitable for milling gears with large diameter by using three-sided milling cutter between teeth on common gear hobbing machine....

28-11-2019 -

Improving the application of three-sided milling cutter in the market

With 335.19 milling cutters and SNHQ blades, you have a perfect combination; the tool lives longer, has better surface quality, and also benefits the machine. ...

28-11-2019