Using ESC technology to improve the durability of cemented carbide thread blades

The ESC (Edge and Surface conditioning) process is a process for the enhancement (passivation) and surface polishing of the cutting edge. Through the ESC process, the tool edge strength can be enhanced, the surface stress state is improved, the surface roughness value is reduced, and the tool durability is 1~4 times.

China's annual oil drilling and production of steel pipe consumption of more than 800,000 tons, the processing of petroleum steel pipe needs to use a large number of threaded blades (a hundred thousand of pieces/year), so the use of ESC technology to improve the quality and durability of threaded blades has significant economic benefits.

1. The shape characteristics of 1 Thread blades This paper is a kind of three-tooth comb blade used for the external thread of the oil casing, and the blade material is YT715 cemented carbide. At the cutting edge of each tooth of blade, 11 characteristic points of A~q are selected, wherein the H point represents the tip of the blade, the A and Q points represent the edge of the root, and the D and L points represent the side of the edge. At high magnification, the blade's edge (i.e. the junction of the front and the back face) is not a simple line, but a complex surface.

The sharpness of the edge is indicated by the radius re. The blade is machined to form a sharp natural edge, as shown in Figure .the radius of the edge of the tooth shape is not uniform (re=0.002~0.018mm).

In order to improve the reliability and stability of cutting tool, the precision honing of the edge by ESC technology can increase the edge strength (increase re), reduce the surface roughness value (ra<0.3μm) and reduce the surface residual stress, so that the edge radius of each point of the blade tooth shape is uniformly consistent.

2. ESC technology and Vibration honing method ESC (Edge and surface hardening treatment) process according to the principle can be divided into mechanical, chemical, electrochemical, abrasive, thermal processing, electromagnetic and other technical methods, such as brush machine honing method, vibration abrasive honing method, sand blasting enhancement method, high-speed particle bombardment method.

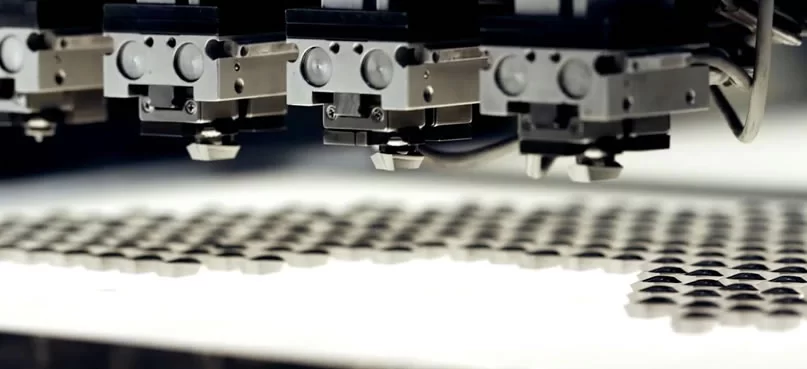

In this paper, vibration abrasive honing method is used to strengthen the edge surface of the thread blade, which is characterized by less investment and lower cost, and can effectively reduce or eliminate the residual stress on the blade surface, thus increasing the durability of the blade. The traditional vibration honing machine is composed of vibrating mechanism (motor, cam, spring, etc.) and worktable, abrasive using sic or alumina particles, blade and abrasive in the box on the workbench, through the blade and abrasive friction, impact to make the edge passivation. However, it is difficult to ensure the uniform radius of the cutting edge, the radius error of the tooth top and the tooth root is 0.02~0.09mm, which affects the machining quality and the effective life of the threaded blade.

In this paper, a new type of mechanical vibration honing method is used to replace the traditional cam and motor mechanism with a new type of vibration motor, the abrasive is a mixture of Emery and boron carbide, and the relative motion between the blade and the abrasive is improved by using the new fixture, so that the tooth top and the edge radius of the The error is controlled within 0.01mm, thereby improving the thread processing pass rate and the blade effective life.