Metal cutting technology and tool development status

Metal cutting technology and tool development status

Since the mid-20th century, due to the fruitful achievements of science and technology such as microelectronics, information technology, and materials science, and the acceleration of engineering progress, the rapid development of manufacturing and manufacturing technology has been promoted. By the end of the 20th century, remarkable results have been achieved. The progress has made a significant contribution to the development of the global economy and is hailed as the engine of the global economy.

Summarizing this history, reviewing the development of human society, economy and civilization, governments have a new understanding of the importance of manufacturing: even today, when high-tech and emerging industries have greatly promoted the economy, manufacturing is still the national economy. And the foundation of comprehensive strength. Paying attention to and accelerating the development of the manufacturing industry has become a powerful country in the world, especially a developing country like China, which has brought rare opportunities and new challenges to the development of manufacturing and manufacturing technology.

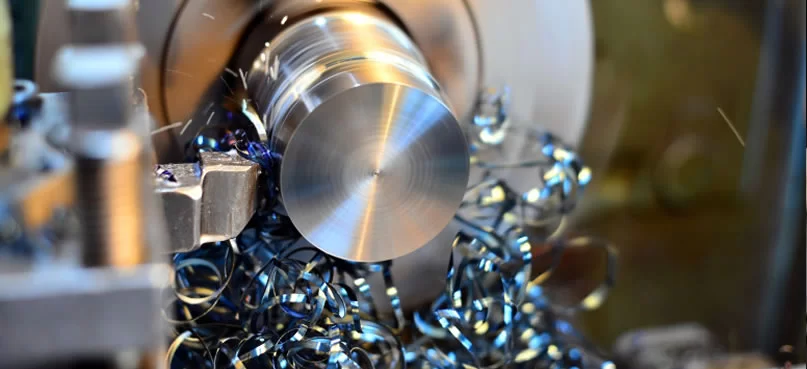

During this period, the metal cutting technology, which is the basic technology of manufacturing technology, has also developed rapidly, and has entered a new stage of development characterized by the development of high-speed cutting, the development of new cutting processes and processing methods, and the provision of complete processing technologies. This is based on the comprehensive advancement and innovation of manufacturing technology, including the comprehensive advancement of CNC machine tools, control systems, tool materials, coating technology, tool structure and other technologies. The comprehensive effects produced by the company have promoted the overall progress of cutting technology. Bring the overall level to a new level. The main feature and technical feature of this height is the high cutting speed (Table 1), marking the cutting process into a new phase of high-speed cutting.

Up to now, high-speed cutting has become an important part of the advanced manufacturing technology and a significant symbol, becoming a key technology in the manufacturing industry, the automotive industry, the aerospace industry, the mold industry and other major industrial sectors. In industrialized countries, high-speed cutting has become a practical new technology. Active development and application of high-speed cutting new technology has become an important measure for enterprises to improve processing efficiency and product quality, reduce manufacturing costs, shorten lead times and improve competitiveness. Significant technical and economic benefits. Therefore, accelerating the development and application of advanced cutting technology represented by high-speed cutting technology has become a consensus in various fields of manufacturing and manufacturing technology in various countries.

Cutting technology and tool development status

First, it has created new technologies such as high-speed cutting, which has improved the processing efficiency.

High-speed cutting presents a unique advantage as a new cutting process. First of all, the cutting efficiency has been significantly improved. Taking the five-piece machining of a car engine as an example, in the past 10 years or so, the production efficiency has been improved by about 1 to 2 times, such as the PCD face milling cutter for processing aluminum alloy cylinder heads. The milling speed has reached 4021m/min and the feed rate is 5670mm/min, which is doubled compared with the production line introduced in China in the early 1990s. For example, the CBN face milling cutter for finishing gray cast iron cylinders has a milling speed of 2000m/ Min, 10 times better than traditional carbide face milling cutters. Second, high-speed cutting is also beneficial to improve product quality, reduce manufacturing costs, and shorten lead times. In addition, on the basis of high-speed cutting technology, new technologies such as dry cutting (quasi-dry cutting, micro-lubricating cutting), hard cutting (by car grinding, milling and grinding) have been developed, which not only improve the processing efficiency but also change the tradition. The boundaries of different cutting operations, and the creation of a new era of cutting manufacturing "green manufacturing." The hard cutting technology has become a highly efficient new process for the machining of the inner hole of the automobile gear and the hardened mold processing. Figure 1 shows the mold for processing 65HRC.

At the same time, high-efficiency machining processes or high-productivity machining processes (HPM, HSM) with high feed rates have emerged according to different processing requirements, reflecting the tremendous development potential of high-speed cutting technology.

Second, the performance of various tool materials based on cemented carbide materials has been comprehensively improved.

The performance of cemented carbide is continuously improved, and the application surface is enlarged, which becomes the main tool material for cutting, which plays an important role in promoting the improvement of cutting efficiency. The first is the development of fine-grained, ultra-fine-grained hard alloy materials, which significantly improve the strength and toughness of cemented carbide materials. The overall hard alloy tools made from it, especially the general-purpose large and medium-sized drill bits. Tools such as end mills and taps are used to replace traditional high-speed steel tools, which increase the cutting speed and machining efficiency by several times. The universal tool with a large amount of face is brought into the range of high-speed cutting, and the cutting process is fully entered. Half of the high-speed cutting stage has been laid. At present, the whole solid carbide tool has become a routine product of domestic and foreign tool companies, and will be more and more widely used as the whole cutting processing level is improved. At present, domestic Hunan Diamond Carbide Tools Co., Ltd., Shanghai Tool Factory Co., Ltd., Siping Xinggong Cutting Tool Co., Ltd. and other enterprises can also produce solid carbide end mills, taps, drills and other products, as shown in Figure 2, Hunan. Solid carbide tool produced by Diamond Carbide.Not only that, but solid carbides are also used in some complex forming tools. Secondly, the development and use of new processes such as cemented carbide pressure sintering have improved the intrinsic quality of cemented carbide; and the development of special grades for different processing needs, and further improved the performance of cemented carbide. In the case of the base material of the chemically coated cemented carbide insert grade, a graded cemented carbide with good resistance to plastic deformation and a tough surface was developed, which improved the cutting performance and application range of the coated cemented carbide insert.

The variety of ceramic and cermet tool materials has increased, the strength and toughness have been improved, the application field and processing range have been expanded, and the hard alloy has been replaced in the finishing and semi-finishing of steel and cast iron, which has improved the processing efficiency and product quality. At present, such tool materials can be used not only in single-piece, small-batch production, but also in mass production of assembly lines, and because of the lower price, they can be used as the preferred tool for dry cutting and hard cutting.

The toughness of the PCD and CBN superhard tool materials and the improvement of the manufacturing process have enabled the application field to expand. Cylinder boring tools made of CBN have been used in automatic production lines as well as in the processing of cast iron and quenching hardware, and have expanded from the finishing field to the semi-finishing field, which has greatly improved the efficiency of cutting. Aluminum alloy is an important material in the aerospace industry and the automotive industry. High-efficiency processing of aluminum alloy is a key technology in these two industrial sectors. At present, due to the wide application of various high-performance tools made with PCD, the cutting efficiency is significantly improved, the highest. The cutting speed has reached 7000m/min. The products have been expanded from the original turning tools and face milling cutters to end mills, drill bits, reamers, forming tools, etc.; PCD is also the only efficient tool for processing non-metallic materials such as graphite and synthetic materials. It can be foreseen that with the promotion of CBN and PCD tools, the variety of tools will further increase, and the application field will be further expanded, leading to the development of cutting processing towards high-speed and high-efficiency machining.

The development of high-speed steel materials is still mentioned in the development of tool materials. Although the sales of high-speed steel tools and cemented carbide tools are reduced by about 5% per year, high-performance cobalt high-speed steel and The use of powder metallurgy high speed steel is increasing. These two high-performance high-speed steels have a long history, they have better wear resistance, red hardness and reliability than ordinary high-speed steel, especially the performance of powder metallurgy high-speed steel, but due to the price High, used to be used in the aerospace industry to process difficult materials. With the pursuit of cutting efficiency and the change of concept, these high-performance high-speed steel tools are first widely used in automatic lines, such as drills, end mills, taps and other general-purpose tools and gear cutters, broaches and other sophisticated tools. Received improved cutting speed and machining quality, reliable use and extended tool life. In recent years, the above-mentioned tools made of high-performance high-speed steel have been expanded and applied to general processing, and have become a conventional product of foreign high-speed steel tools.

In summary, in the development of various tool materials, cemented carbide plays a leading role, but the performance of other tool materials has also been significantly improved, expanding their respective application areas, forming a variety of tool materials. There are unique advantages and scope of use that replace each other to complement the overall pattern. It can be said that the comprehensive and rapid development of tool materials has laid the foundation for today's high-speed, high-efficiency metal cutting.

Third, coatings are a key technology to improve tool performance.

The coating technology of the tool plays an important role in the development of modern cutting and cutting tools. It has developed very rapidly since its inception, especially in recent years. Chemical coating (CVD) is still the main coating process for indexable inserts. New processes such as medium temperature CVD, thick film aluminum oxide, and transition layer have been developed. Based on the improvement of the base material, the CVD coating is resistant. Both wear and toughness are improved; CVD diamond coatings have also made progress, improving the surface finish of the coating and entering a practical stage. At present, the coating ratio of foreign carbide indexable inserts has reached more than 70%. During this period, the progress of physical coating (PVD) has been particularly noticeable, and significant progress has been made in furnace structure, process, and automatic control, and not only heat resistance suitable for high-speed cutting, dry cutting, and hard cutting has been developed. Better coatings, such as Super TiAlN, and TiAlCN general-purpose coatings with better overall performance and DLC, W/C anti-friction coatings, and through the innovation of coating structure, developed nano- and multi-layer structures, Improves coating hardness and toughness. Table 2 shows the latest coatings from the Swiss company PLATIT.

The new development of PVD coating technology shows us the great potential and unique advantages of coating technology for improving tool performance: new coatings can be developed through the control of coating process parameters and the adjustment of target and reaction gases. To meet the needs of processing diversity, it is a fast and good technology to improve and improve tool performance, and has a very broad application prospect.

Fourth, the innovation of tool structure has changed the face and the single function of traditional standard tools.

With the rapid development of the manufacturing industry, key industries such as the automotive industry, aerospace industry and mold industry have put forward higher requirements for cutting processing, and promoted the continuous development of indexable tools. The special set of tools developed for the automobile industry assembly line has broken through the traditional practice of supplying tools on demand and “closed door making”, and has become an important technological factor for innovative processing technology, improving processing efficiency and saving investment, and playing a new role. Figure 3 is a high-speed milling cutter for WIDIA's new process for crankshaft machining.

The mold industry is characterized by high efficiency, single piece, small batch production, high hardness of mold materials, difficult processing, complex shape, large amount of metal removal, short delivery period, and become a powerful driving force for the innovation of indexable tool structure, such as Functional face milling cutters, various ball end milling cutters, modular end mill systems, boring and milling cutters, large feed milling cutters, etc. Looking back at the development of cutting processing since the 1990s, the mold industry is still the birthplace of new high-speed cutting, hard cutting and dry cutting processes.

In order to meet the needs of the aerospace industry to efficiently process large aluminum alloy components, a new high-speed aluminum alloy face milling cutter and other tools have been developed. Figure 4 is a high-speed face milling cutter from Sandvik, with a maximum speed of 24000r/min and cutting speed. It is 6000m/min.

At the same time, new structures for indexable inserts have emerged, such as high-efficiency blister blades for turning, complex-sized milling cutter blades with anterior corners, ball-end end mill blades, and high-speed anti-smashing blades. Milling cutter blades and so on.

With the improvement of the function of the five-axis linkage CNC tool grinding machine and the popularization of its application, the geometric parameters of standard universal tools such as end mills and drill bits are more diversified, which changes the old pattern of traditional standard tools and can adapt to different processed materials and Processing conditions, cutting performance increased accordingly. Some innovative structures also produce new cutting effects, such as unequal helix angle end mills. Compared with standard end mills, unequal helix angle end mills can effectively curb tool vibration, improve machining finish, and increase tooling. Cutting depth and feed rate. For example, various carbide drills of different drill tip types and different groove types, Figure 5 are various drill bits and different drill tip grinding forms introduced by Shanghai Tool Works Co., Ltd. to adapt to different materials. The development of carbide taps and carbide thread milling cutters improves the efficiency of thread processing to the level of high-speed cutting. In particular, carbide thread milling cutters not only have high processing efficiency, but also have good versatility, which can save tool costs.

Fifth, the rapid development of supporting technologies.

The cutting technology is gradually developed along with the advancement of cutting technology. It is an indispensable part of modern cutting technology and maintains rapid development with cutting technology and tools, including between the tool holder and the machine tool spindle. Connection method, tool clamping in the tool holder, tool system balance and tool management.

The double-sided hollow hollow taper shank (HSK) machine tool-tool interface has the advantages of good connection rigidity, high positioning accuracy, short loading and unloading time, etc. The promotion of technology has been used more and more widely (Figure 6). The structure of this tool holder has become an official international standard, and has been accepted by many machine tool manufacturers. It has introduced high-speed machining centers with HSK spindle interfaces and tool systems or integrated tools with HSK tool holders. The powerful vitality and good use prospect of this new type of tool holder. At the same time, some companies have developed shank structures similar to HSK, such as Sandvik's Capto shank and Kennametal's KM shank. In recent years, there has also been a 7:24 interface for double-sided contact or even three contacts to accommodate the needs of existing machine tools for high-speed machining.

The use of high-speed rotating tools also places new demands on tool clamping. It requires high clamping precision, radial runout <0.003mm, good clamping rigidity, compact structure and easy operation. The chuck for the mold milling cutter also requires overhang and the outer shape is small, which facilitates the machining of the inside of the cavity. The three new types of chucks that are currently more common are: hydraulic chucks, hot chucks and force shrink chucks. The hydraulic chuck is clamped by the thin-walled inner sleeve of the hydraulic chamber to clamp the shank. Compared with the latter two types of chucks, the deformation of the sleeve allows the diameter of the shank to be slightly changed, and the oil chamber has the damping effect of vibration damping. It is easy to use, but the thin-walled sleeve has low clamping rigidity and asymmetrical structure. The hot chuck is to use the principle of thermal expansion and contraction to clamp the shank when the chuck is cooled. This clamping method is suitable for cavity machining due to reliable clamping, compact structure, small size and overhang. It is currently widely used. The force-shrinking chuck is generated by mechanical elastic deformation, which saves time and energy for heat-shrinking chuck heating and cooling, is convenient to use and has controllable axial positioning accuracy, and is simple in operation, but has a large outer shape.

In addition, there is a balance and safety requirement for high-speed rotating tools. Due to structural asymmetry or eccentricity caused by manufacturing and assembly errors, there is an imbalance between the center of rotation and the high-speed rotation. The periodic radial force acts on the bearing system of the spindle and even on other parts of the machine, affecting the quality of the machining, the life of the tool and the performance of the machine. To this end, the allowable unbalance and high-speed use of high-speed rotary tools are specified; tool manufacturers have developed a variety of adjustable balance tools, or rotary tools and tool systems for high-speed cutting before loading into the spindle. Balance on the dynamic balancing machine to limit the imbalance to a certain range. In order to reduce the amount of unbalance (eccentricity) generated after the tool is loaded into the spindle, the new online automatic balancing technology balances the spindle, the shank and the tool as a rotor system at the operating speed.

In high-speed cutting, the speed of the tool is higher than 10,000~20000r/min or even higher. At this time, the clamping parts of the blade body, the blade and the blade are subjected to a large centrifugal force. When the rotation speed reaches a certain critical value, it is sufficient. The blade is pulled out, or the clamping screw is broken, or even the entire body is broken. In the event of these conditions, equipment or personal injury can result in accidents, so it is a must to prevent high-speed cutting technology. To this end, Germany has developed a safety specification for high-speed rotating tools, which has strict regulations on the design, testing, use and balance quality of the tool. This specification has become a European standard and an international standard.

According to the data, the direct cost of the tool only accounts for 2%~4% of the manufacturing cost, while the cost of tool use and management is more than 12%. The scientific tool management can save the user considerable tool cost and reduce the manufacturing cost. Therefore, the development of tool management technology and related software and hardware has become the business scope of tool manufacturers, providing users with various forms of tool management services, from simple tool logistics management to package contracting of all tool businesses, including Tool procurement, identification, storage, on-site service, tool re-grinding, process improvement, project development, etc. User companies can take advantage of this specialized social service, maintain a high level of cutting processing, and focus on the development of core technology, and achieve a double harvest of economic and technological.

Sixth, the new business model of the tool industry.

With the development of cutting technology, the tool industry is undergoing a revolution in operating mechanisms. Faced with an increasingly new production model and new workpiece materials, “tools” are no longer simple products. Once sold, they are important process factors for optimizing a process or a line processing technology. Tool manufacturers must be able to Providing users with complete processing technology to help users achieve the goal of improving processing efficiency, product quality and reducing manufacturing costs has become the direction and business purpose of foreign tool manufacturers' business development. At present, tool manufacturers have brought the tool industry to a higher stage of development through various forms of business services such as “serving users” and “providing solutions”. Facts have proved that this practice of foreign tool manufacturers is conducive to the development of the manufacturing industry, bringing more benefits to users and being welcomed by users.

Apply advanced cutting technology to accelerate the development of China's manufacturing industry

The 16th National Congress of the Communist Party of China put forward the task of building a well-off society in an all-round way and realizing new industrialization. It blew the horn of China's march from a manufacturing power to a manufacturing power. As the basic technology of manufacturing technology, cutting tool is the basic process equipment. It is in the first position in this historic march. Advanced cutting technology and cutting tools are China's development of automobile industry, aerospace industry, energy industry and supporting equipment. Prerequisites for the mold industry. In the face of such a great opportunity, we must make full use of advanced cutting technology and cutting tools to serve China's manufacturing industry.

To this end, China's tool industry is accelerating its integration with the world's tool industry, introducing advanced process equipment and technology through technological transformation, and developing and producing first-class tool products. China's tool industry's two vanguards - Zhuzhou Cemented Carbide Group and Shanghai Tool Factory Co., Ltd. took the lead in carrying out technological transformation with high starting point and large investment, which made the technology of manufacturing indexable inserts and solid carbide tools in China close. The world's advanced level. At the same time, foreign tool companies are facing the rapid development of China's manufacturing industry and the prospects for rapid development, speeding up the pace of localized production or service in China, in order to reduce manufacturing costs, improve service capabilities, and shorten lead times. It is said that the entry of foreign tool companies into the Chinese market provides very favorable conditions for us to apply advanced tools to transform traditional manufacturing. We must seize this favorable opportunity and actively adopt advanced cutting tools to meet the challenges of economic globalization in order to improve the processing technology and competitive strength of enterprises.

When enterprises accelerate the application of advanced cutting technology, the situation of each enterprise is different, and the specific practices are different, but the following points can be used as a common idea:

Tools made of high-performance tool materials, including solid carbide tools, silicon nitride ceramic tools, CBN and PCD tools, high-performance high-speed steel tools, etc., one kind of introduction for the specific situation of production, step by step Push, will receive good results; currently the domestic tool manufacturers can also partially supply these tool products.

Greatly use coated tools. The proportion of coated knives in China is very low, and there is a large space for promotion. The appropriate coating grade should be selected according to the processing conditions and needs to achieve the desired results.

The use of indexable tools is strongly used. Indexable tools have been promoted in China for many years, but progress has not been fast enough for various reasons.

Development is not balanced. However, during this period, the technology of indexable tools has made new progress, the variety has increased rapidly, and it has developed in a more efficient and applicable direction. Curved edge milling cutter blades, turning inserts with wiper blades and general purpose have been developed. Products with good circular blades and octagonal blades have great potential for application. Actively promoting indexable tools should become an important project for technological transformation of enterprises. Figure 7 is a curved edge insert milling cutter developed by Hunan Diamond Cutting Tool Co., Ltd.

For large-scale production lines, we must learn from foreign experience, develop new processes and special tools, improve efficiency and reduce costs, or develop combined tool concentration processes to improve efficiency and reduce investment. Such work must be combined with machine tool builders and tool manufacturers to achieve results. This is a mature practice in industrialized countries.

For companies with a single-piece small batch production mode, efficient new tools such as internal cooling drills and rake face end mills should be used. Secondly, multi-function universal cutters can be used, which can reduce the time of tool change. It is also necessary to break the traditional process limits of drilling, milling, grinding, etc., and to achieve new processing effects through the process of milling, drilling, milling, milling, milling, and grinding. In addition, strengthen tool management, reduce inventory and reduce tooling costs.

When adopting advanced cutting tools and new technologies, enterprises must rely on the technical strength of tool manufacturers and distributors to follow the path of socialization. In the current situation of new workpiece materials, tool materials and coating grades, there are thousands of types of tools. Only with the help of their professionals can you choose the right tool and achieve the desired goal. This is also the current foreign tool manufacturing. The business philosophy of “system supply” and “providing solutions” actively promoted by the company. Secondly, it is necessary to break the incorrect concept of the cost of the tool--thinking that the good tool is too expensive to spend. It is this view that has long affected the progress of cutting technology in China and the development of the national tool industry. The tool is “expensive” and only accounts for 2%~4% of the manufacturing cost (less than 2% in most enterprises in China). Only by using the “expensive” knife, the efficiency can be greatly reduced to greatly reduce the cost of a single piece. The benefits of the enterprise will eventually achieve the effect of less investment and more output. Through specific processing examples, it can be proved that the cost of the tool is not more than that of each product.

Finally, I hope that through the efforts of everyone, the cutting technology of this unit will be put together to contribute to the advancement of China's manufacturing and manufacturing technologies.