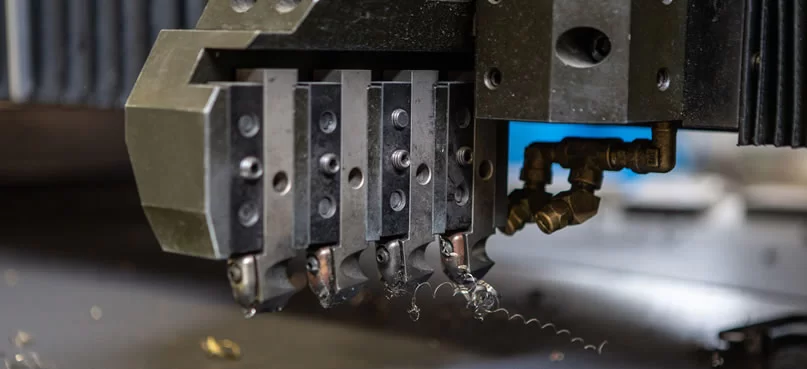

Introduction to the use of cutting grooving blades

Turning tools and applications Turning tools are the most widely used single-edged tool. It is also the basis for learning and analyzing various types of tools. Turning tools are used in all kinds of lathes. Turning tools On the turning tools, the outer circle, inner hole, end face, thread, and groove are machined. According to the structure, the turning tool can be divided into an overall turning tool, a welding turning tool, a machine clamping turning tool, an indexable turning tool and a forming turning tool. Among them, the application of indexable turning tools is increasingly widespread, and the proportion in turning tools is gradually increasing. 1. Carbide welding turning tool The so-called welding type turning tool is to open the sipe on the carbon steel arbor according to the geometrical requirements of the tool, and weld the cemented carbide insert into the sipe with solder, and according to the selected The turning tool used after the geometric parameters are sharpened. The machine tool is a turning tool that uses a common blade to clamp the blade to the tool holder by mechanical clamping.

The distinction between the shape of the blade:

(1) Right hand turning tool: Turn right and left to turn the outer diameter of the workpiece. (2) Left-hand turning tool: Turn left to right, turning the outer diameter of the workpiece. (3) Round nose knife: The blade has a circular arc shape and can be turned in the left and right direction, suitable for turning of rounded corners or curved surfaces. (4) Right side turning tool: Turn the right end face. (5) Left side turning tool: Turn the left end face. (6) Cutting knife: used for cutting or grooving. (7) Inner hole turning tool: used to turn the inner hole. (8) External thread turning tool: used for turning external thread. (9) Internal thread turning tool: used for turning internal thread. If you want to do something good, you must first sharpen your tools. In order to make good cutting on the lathe, it is very important to properly prepare and use the tool. Different work requires different shapes of turning tools. Cutting different materials requires different angles of the knife edge. The position and speed of the turning tool and the work object should have a certain relative relationship. The turning tool itself should also have sufficient hardness and strength. Wear and heat resistant. Therefore, how to choose the turning tool material, the grinding of the tool angle is an important consideration.

The cutting grooving blade has the following characteristics: (1) The tool durability is improved, the use time is long, the tool change time is shortened, and the production efficiency is improved. (2) The end of the pressure plate used for pressing the blade can function as a chip breaker. Mechanical clamping type tool (1) The blade is not subjected to high temperature welding, which avoids defects such as hardness drop and cracking caused by welding, and improves the durability of the tool. (3) After the blade is reground, the size will gradually become smaller. In order to restore the working position of the blade, a blade adjustment mechanism is often provided on the turning structure to increase the number of regrind of the blade. (4) The end of the pressure plate used for pressing the blade can function as a chip breaker. 4. Indexable turning tool The indexable turning tool is a machine clamping cutter that uses an indexable insert. After a cutting edge is blunt, it can be quickly indexed and replaced with an adjacent new cutting edge to continue working until all the cutting edges on the blade have been blunt, and the blade is scrapped and recycled. After replacing the new blade, the turning tool can continue to work.