Kenyelletso ea tšebeliso ea li-blades tsa grooving

Lisebelisoa tsa ho fetola le lisebelisoa Lisebelisoa tsa ho fetola ke tsona tse sebelisoang ka ho fetisisa tse nang le moeli o le mong. Hape ke motheo oa ho ithuta le ho sekaseka mefuta e fapaneng ea ...

2019-11-28-

Carbide sesebelisoa se sa tloaelehang

T-slot milling cutter, "Carbide non-standard tool": E sebelisa tšepe ea lebelo le holimo le motsoako o thata ho sebetsa tšepe e tloaelehileng e sehang habonolo (HRC30 kapa ka tlase), 'me e ka etsoa ka tšepe ea lebelo le holimo....

28-11-2019 -

Theknoloji ea ho itšeha ka tšepe le boemo ba ntlafatso ea lisebelisoa

Ho tloha bohareng ba lekholo la bo20 la lilemo, ka lebaka la likatleho tse behang litholoana tsa saense le thekenoloji tse kang microelectronics, theknoloji ea boitsebiso, le saense ea thepa, le ho potlakisa tsoelo-pele ea boenjiniere, tsoelo-pele e potlakileng ea tlhahiso le theknoloji ea tlhahiso ...

28-11-2019 -

Ho sebelisa theknoloji ea ESC ho ntlafatsa ho tšoarella ha likhoele tse entsoeng ka samente ea carbide

Ts'ebetso ea ESC (Edge le Surface conditioning) ke ts'ebetso ea ho ntlafatsa (passivation) le ho bentša bokaholimo ba moeli o sehang. Ka ts'ebetso ea ESC, matla a moeli oa lisebelisoa a ka ntlafatsoa, boemo ba khatello ea maikutlo bo ka ntlafatsoa, boleng ba bokaholimo bo fokotsehile, 'me ho tšo...

28-11-2019 -

Tšebeliso ea li-graphics tsa ho itšeha bakeng sa likhoele tsa likhoele tsa peipi ea oli

Mokhoa oa ho qapa palo ea ho itšeha ea mohaho o mong le o mong oa leino le ho ajoa ha moroalo oa ho itšeha oa leino le leng le le leng ho bohlokoa haholo bakeng sa ho ntlafatsa le ho hatela pele boleng, katleho le bophelo ba sesebelisoa sa khoele ea screw....

28-11-2019 -

Maqhubu a likhoele tse peli tsa menoana

Tsoelo-pele ea morao-rao ea thekenoloji ea ho itšeha ka khoele ke lehare le nang le sebōpeho se khethehileng sa geometri (meno a mabeli a nang le li-contours tse fapaneng). Motsoako ona o lumella palo ea lichapo hore e thehe khoele e feletseng hore e fokotsehe ka hoo e ka bang 40% ha e bapisoa le se...

28-11-2019 -

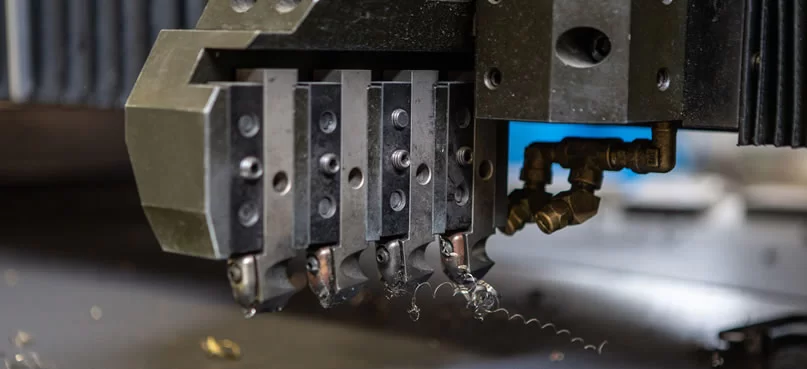

Tshebediso ya mahlakore a mararo a mahlakore a mararo a sila

Ho phaella karolong e ka sehloohong ea ho itšeha ea holim'a selikalikoe, sekontiri sa mahlakoreng a mararo se na le lehlakoreng la ho itšeha, e leng se ntlafatsang boemo ba ho itšeha, ho ntlafatsa bokhoni ba ho itšeha le ho fokotsa ho hlaba holimo....

28-11-2019 -

Ho atolosoa ha leloala la mahlakore a mararo

Basemi ba lithaba tse phahameng ba ekelitse mefuta e 'meli e mecha ea li-griller tse mahlakoreng a mararo sebakeng se pharaletseng ka ho fetisisa 'marakeng. Ka li-cutters tse 335.19 le li-blades tsa SNHQ, u na le motsoako o phethahetseng; sesebelisoa se phela nako e teletsana, se na le boleng bo hol...

28-11-2019 -

mokhoa oa ho sila o mahoashe oa meno a maholo a modulus a nang le sehahi sa mahlakore a mararo

E loketse lisebelisoa tsa ho sila tse nang le bophara bo boholo ka ho sebelisa seha se nang le mahlakore a mararo pakeng tsa meno mochining o tloaelehileng oa ho hoa....

28-11-2019 -

Ho ntlafatsa ts'ebeliso ea seha se nang le mahlakore a mararo 'marakeng

Ka li-cutters tse 335.19 le li-blades tsa SNHQ, u na le motsoako o phethahetseng; sesebelisoa se phela nako e teletsana, se na le boleng bo holimo bo holimo, hape se thusa mochini....

28-11-2019