Ho sebelisa theknoloji ea ESC ho ntlafatsa ho tšoarella ha likhoele tse entsoeng ka samente ea carbide

Ts'ebetso ea ESC (Edge le Surface conditioning) ke ts'ebetso ea ho ntlafatsa (passivation) le ho bentša bokaholimo ba moeli o sehang. Ka ts'ebetso ea ESC, matla a moeli oa lisebelisoa a ka ntlafatsoa, boemo ba khatello ea maikutlo bo ka ntlafatsoa, boleng ba bokaholimo bo fokotsehile, 'me ho tšoarella ha sesebelisoa ke makhetlo a 1 ~ 4.

Ho cheka oli ea selemo le selemo ea China le tlhahiso ea tšebeliso ea lipeipi tsa tšepe tsa lithane tse fetang 800,000, ts'ebetso ea phala ea tšepe ea peterole e hloka ho sebelisa palo e kholo ea mahare a khoele (likotoana tse likete tse lekholo / selemo), kahoo ts'ebeliso ea theknoloji ea ESC ho ntlafatsa boleng le ho tšoarella ha li-blades tse khoele li na le melemo e mengata ea moruo.

1. Litšobotsi tsa sebopeho sa li-blades tsa 1 Thread blades Pampiri ena ke mofuta oa lehare la khekhe la meno a mararo le sebelisetsoang khoele e ka ntle ea casing ea oli, 'me thepa ea lehare ke YT715 e entsoeng ka cemented carbide. Qetellong ea leino le leng le le leng la lehare, ho khethoa lintlha tse 11 tsa A~q, moo ntlha ea H e emelang ntlha ea lehare, lintlha tsa A le Q li emela moeli oa motso, 'me lintlha tsa D le L li emela ntlha. lehlakore la mothapo. Ha ho phahamisoa ka holimo, moeli oa lehare (e leng ho kopana ha sefahleho se ka pele le se ka morao) hase mohala o bonolo, empa ke sebaka se rarahaneng.

Bohale ba bohale bo bontšoa ke radius re. Lehare le entsoe ka mochine ho etsa moeli o bohale oa tlhaho, joalokaha ho bontšitsoe Setšoantšong.

E le ho ntlafatsa ho tšepahala le ho tsitsa ha sesebelisoa sa ho itšeha, ho hong ho nepahetseng ha moeli ka theknoloji ea ESC ho ka eketsa matla a bohale (ho eketsa re), ho fokotsa boleng ba holim'a metsi (ra

2. ESC theknoloji le Vibration honing mokhoa ESC (Edge le holim'a ka thatafatsa kalafo) tshebetso ho ea ka molao-motheo e ka aroloa ka mechine, lik'hemik'hale, electrochemical, abrasive, mocheso tshebetso, electromagnetic le mekhoa e meng ea botekgeniki, tse kang borashe mochini honing mokhoa, vibration. mokhoa oa ho ntlafatsa ho phatloha ha lehlabathe, mokhoa oa ho phahamisa lehlabathe ka lebelo le phahameng.

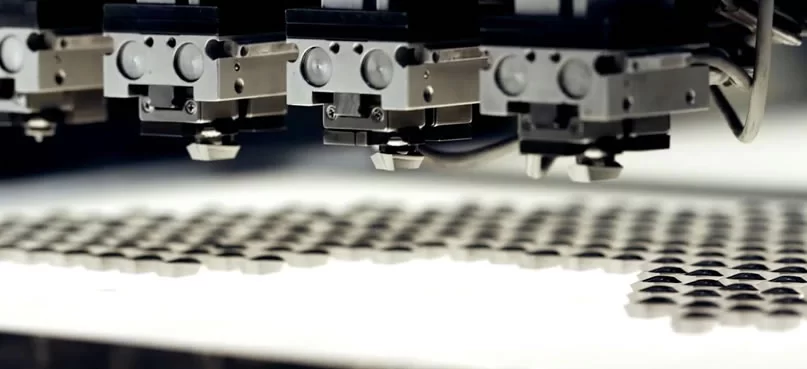

Ka pampiri ena, ho thothomela abrasive honing mokhoa o sebelisoa ho matlafatsa bohale holim'a lehare la khoele, e leng tšoauoa ka tlase dipeeletso le theko e tlaase, 'me ka katleho fokotsa kapa ho felisa khatello ea kelello e setseng holim'a lehare, kahoo eketsa durability ea lehare. Mochini o tloaelehileng oa ho thothomela o entsoe ka mochini o thothomelang (motoro, cam, selemo, joalo-joalo) le o sebetsang, o senya o sebelisa likaroloana tsa sic kapa alumina, lehare le abrasive ka lebokoseng le bencheng ea mosebetsi, ka lehare le likhohlano tsa abrasive, tšusumetso ho etsa. tjantjello. Leha ho le joalo, ho thata ho netefatsa radius e ts'oanang ea moeli oa ho itšeha, phoso ea radius ea top top le motso oa leino ke 0.02 ~ 0.09mm, e amang boleng ba machining le bophelo bo sebetsang ba lehare le khoele.

Pampiring ena, ho sebelisoa mofuta o mocha oa mokhoa oa ho honotha oa mochini ho fetola mochini oa khale oa cam le motor ka mofuta o mocha oa enjene ea vibration, abrasive ke motsoako oa Emery le boron carbide, le motsamao o lekanyelitsoeng lipakeng tsa lehare le abrasive e ntlafatsoa ka ho sebelisa sesebelisoa se secha, e le hore karolo e ka holimo ea leino le bohale ba radius ea Phoso e laoloe ka hare ho 0.01mm, ka tsela eo e ntlafatsa sekhahla sa ho feta ha khoele le bophelo bo sebetsang.