Kusetshenziswa ubuchwepheshe be-ESC ukwenza ngcono ukuqina kwezintambo zikasimende ze-carbide

Inqubo ye-ESC (Edge kanye ne-Surface conditioning) iyinqubo yokuthuthukisa (i-passivation) kanye nokupholisha ubuso bonqenqema lokusika. Ngenqubo ye-ESC, amandla onqenqema lwethuluzi angathuthukiswa, isimo sokucindezelwa kwangaphezulu siyathuthukiswa, inani lokuma okungaphezulu liyancishiswa, futhi ukuqina kwethuluzi izikhathi ezi-1 ~ 4.

Ukumba kawoyela ngonyaka kanye nokukhiqizwa kwamapayipi ensimbi ensimbi amathani angaphezu kuka-800,000, ukucutshungulwa kwepayipi lensimbi ye-petroleum kudinga ukusebenzisa inani elikhulu lama-threaded blades (izinkulungwane eziyikhulu zezingcezu / ngonyaka), ngakho-ke ukusetshenziswa kobuchwepheshe be-ESC ukuthuthukisa ikhwalithi nokuqina kwama-threaded blades kunezinzuzo ezibalulekile zezomnotho.

1. Izici zomumo zama-thread blades angu-1 Leli phepha liwuhlobo lwe-blade yekama enamazinyo amathathu esetshenziselwa intambo yangaphandle ye-casing kawoyela, kanti i-blade yi-YT715 cemented carbide. Onqenqemeni lwezinyo ngalinye, amaphuzu ayi-11 we-A~q akhethiwe, lapho iphoyinti lika-H limelela ichopho lensingo, amaphuzu u-A no-Q amelela unqenqema lwempande, kanti amaphuzu ka-D no-L amelela. ohlangothini onqenqemeni. Ekukhuliseni okuphezulu, unqenqema lwe-blade (okungukuthi ukuhlangana kobuso bangaphambili nangemuva) akuwona umugqa olula, kodwa indawo eyinkimbinkimbi.

Ubukhali bonqenqema buboniswa iradius re. I-blade ifakwe ngomshini ukuze yakhe unqenqema lwemvelo olubukhali, njengoba kuboniswe kuMfanekiso .i-radius yonqenqema lwesimo sezinyo ayifani (re=0.002 ~ 0.018mm).

Ukuze kuthuthukiswe ukuthembeka nokuzinza kwethuluzi lokusika, ukucija ngokunemba konqenqema ngobuchwepheshe be-ESC kungakhuphula amandla onqenqema (ukwandisa kabusha), kunciphise inani lobunzima bobuso (ra

2. Ubuchwepheshe be-ESC kanye ne-Vibration honing indlela ye-ESC (I-Edge kanye nokwelashwa kokuqina kobuso) inqubo ngokusho kwesimiso ingahlukaniswa ngomshini, amakhemikhali, i-electrochemical, i-abrasive, i-thermal processing, i-electromagnetic kanye nezinye izindlela zobuchwepheshe, njenge-brush machine honing method, vibration. indlela ye-abrasive honing, indlela yokuthuthukisa ukuqhunyiswa kwesihlabathi, indlela yokuqhuma kwezinhlayiyana ezinesivinini esikhulu.

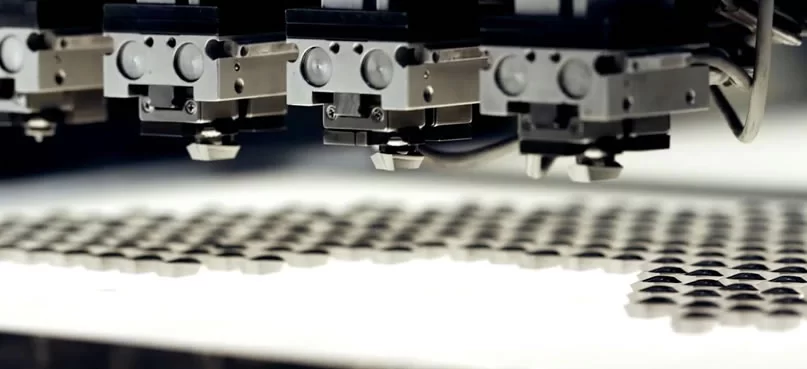

Kuleli phepha, indlela ye-vibration abrasive honing isetshenziselwa ukuqinisa indawo esemaphethelweni ye-thread blade, ebonakala ngokutshalwa kwezimali okuncane kanye nezindleko eziphansi, futhi inganciphisa ngempumelelo noma iqede ukucindezeleka okusele endaweni ye-blade, ngaleyo ndlela kwandise ukuqina kwe-blade. ucezu. Umshini wokucija ukudlidliza ongokwesiko wakhiwe ngendlela yokudlidliza (injini, ikhamera, intwasahlobo, njll.) kanye ne-worktable, i-abrasive kusetshenziswa izinhlayiya ze-sic noma ze-alumina, i-blade kanye ne-abrasive ebhokisini ebhentshini lokusebenzela, ngokusebenzisa i-blade kanye nokungqubuzana okuhuzukayo, umthelela wokwenziwa. i-edge passivation. Kodwa-ke, kunzima ukuqinisekisa i-radius efanayo yonqenqema lokusika, iphutha le-radius phezulu kwezinyo kanye nempande yezinyo ngu-0.02 ~ 0.09mm, okuthinta ikhwalithi yomshini kanye nempilo ephumelelayo ye-blade ene-threaded.

Kuleli phepha, uhlobo olusha lwendlela yokucija yokudlidliza esetshenziswayo isetshenziswa esikhundleni sekhamera yendabuko neyesithuthuthu kufakwe uhlobo olusha lwenjini yokudlidliza, i-abrasive iyingxube ye-Emery ne-boron carbide, kanye nokunyakaza okuhlobene phakathi kweblade nensimbi. i-abrasive ithuthukiswa ngokusebenzisa into entsha, ukuze ingaphezulu lezinyo nendawo yonqenqema ye-Iphutha lilawuleke ngaphakathi kuka-0.01mm, ngaleyo ndlela kuthuthukiswe izinga lokuphasa kokucubungula intambo nokuphila okusebenzayo kweblade.