Isingeniso sokusebenzisa ama-grooving blades

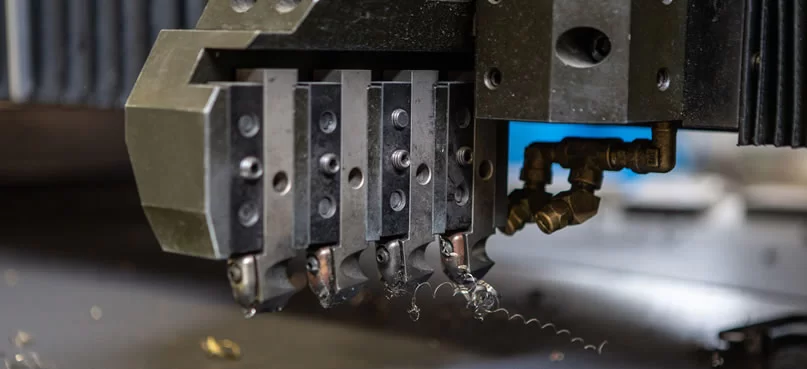

Amathuluzi okuguqula kanye nezinhlelo Amathuluzi okuguqula iyithuluzi elisetshenziswa kakhulu elinomphetho owodwa. Futhi kuyisisekelo sokufunda nokuhlaziya izinhlobo ezahlukene zamathuluzi. Amathuluzi okuguqula asetshenziswa kuzo zonke izinhlobo zezintambo. Amathuluzi okuguqula Kumathuluzi okujika, indilinga engaphandle, imbobo engaphakathi, ubuso bokuphela, intambo, kanye nomsele wenziwe ngomshini. Ngokusho kwesakhiwo, ithuluzi lokuguqula lingahlukaniswa libe yithuluzi eliguqukayo jikelele, ithuluzi lokuguqula i-welding, ithuluzi lokuguqula i-clamping, ithuluzi lokuguqula i-indexable kanye nethuluzi lokuguqula. Phakathi kwazo, ukusetshenziswa kwamathuluzi okuguqula okunenkomba kuyanda, futhi isilinganiso samathuluzi okuguqula siyakhula kancane kancane. 1. Ithuluzi lokuguqula i-Carbide welding Ithuluzi lokuguqula uhlobo lwe-welding ukuvula i-sipe ku-arbor yensimbi ye-carbon ngokuvumelana nezidingo ze-geometrical zethuluzi, bese ufaka i-carbide enosimende efaka esipeni nge-solder, futhi ngokusho okukhethiwe. Ithuluzi lokuguqula elisetshenziswe ngemuva kokuba imingcele yejometri ibukhali. Ithuluzi lomshini ithuluzi elijikayo elisebenzisa i-blade evamile ukubophela i-blade kusiphathi samathuluzi ngokucindezela ngomshini.

Umehluko phakathi komumo we-blade:

(1) Ithuluzi lokujika kwesokudla: Jikela kwesokudla nakwesokunxele ukuze uvule ububanzi obungaphandle bomsebenzi wokusebenza. (2) Ithuluzi lokujika kwesokunxele: Jikela kwesokunxele uye kwesokudla, uphendulela ububanzi obungaphandle bomsebenzi wokusebenza. (3) Ummese wekhala eliyindilinga: I-blade inesimo se-arc esiyindilinga futhi ingaphendulwa iqonde kwesokunxele nesokudla, ifanele ukuphenduka kwamakhona ayindilinga noma izindawo ezigobile. (4) Ithuluzi lokujika ohlangothini lwesokudla: Guqula ubuso bokuphela kwesokudla. (5) Ithuluzi lokujika kwesokunxele: Vula ubuso bokuphela kwesokunxele. (6) Ummese wokusika: usetshenziselwa ukusika noma ukugwaza. (7) Ithuluzi lokuguqula imbobo engaphakathi: esetshenziswa ukujika imbobo engaphakathi. (8) Ithuluzi lokujika intambo yangaphandle: isetshenziselwa ukuphendulela intambo yangaphandle. (9) Ithuluzi lokuphendula intambo yangaphakathi: isetshenziselwa ukuphendulela intambo yangaphakathi. Uma ufuna ukwenza okuthile okuhle, kufanele uqale ulole amathuluzi akho. Ukuze wenze ukusika okuhle ku-lathe, kubaluleke kakhulu ukulungiselela kahle nokusebenzisa ithuluzi. Umsebenzi ohlukile udinga izimo ezihlukene zamathuluzi okuguqula. Ukusika izinto ezihlukene kudinga ama-engeli ahlukene onqenqema lommese. Isikhundla nesivinini sethuluzi lokuguqula kanye nento yokusebenza kufanele ibe nobudlelwane obuthile obuhlobene. Ithuluzi lokuguqula ngokwalo kufanele futhi libe nobulukhuni obanele namandla. Ukumelana nokugqoka nokushisa. Ngakho-ke, indlela yokukhetha ithuluzi lokuguqula impahla, ukugaya i-angle yamathuluzi kuwukucatshangelwa okubalulekile.

I-cutting blade inezici ezilandelayo: (1) Ukuqina kwethuluzi kuyathuthukiswa, isikhathi sokusebenzisa side, isikhathi sokushintsha ithuluzi sifinyezwa, kanye nokusebenza kahle kokukhiqiza kuyathuthukiswa. (2) Ukuphela kwepuleti lokucindezela elisetshenziselwa ukucindezela i-blade kungasebenza njenge-chip breaker. Ithuluzi lohlobo lokubopha ngomshini (1) I-blade ayifakwa ngaphansi kwezinga lokushisa eliphezulu, eligwema izici ezinjengokwehla kokuqina nokuqhekeka okubangelwa ukushisela, futhi ithuthukisa ukuqina kwethuluzi. (3) Ngemva kokuba i-blade igaywe kabusha, usayizi uzoncipha kancane kancane. Ukuze ubuyisele indawo yokusebenza ye-blade, indlela yokulungiswa kwe-blade ivame ukunikezwa esakhiweni esiphendukayo ukuze kwandiswe inani lokugaywa kabusha kwe-blade. (4) Ukuphela kwepuleti lokucindezela elisetshenziselwa ukucindezela i-blade kungasebenza njenge-chip breaker. 4. Ithuluzi lokujika elinenkomba Ithuluzi lokujika elinenkomba wumshini wokusika umshini osebenzisa okokufaka okunenkomba. Ngemuva kokuthi unqenqema lokusika lubuthuntu, lungakhonjwa ngokushesha futhi esikhundleni salo kufakwe unqenqema olusha oluseduze ukuze luqhubeke nokusebenza kuze kube yilapho yonke imiphetho yokusika i-blade ibe buthuntu, futhi i-blade iyachithwa futhi igaywe kabusha. Ngemva kokufaka i-blade entsha, ithuluzi lokuguqula lingaqhubeka nokusebenza.