Siv ESC thev naus laus zis los txhim kho lub zog ntawm cov cemented carbide xov hniav

Cov txheej txheem ESC (Edge thiab Surface conditioning) yog txheej txheem rau kev txhim kho (passivation) thiab polishing nto ntawm ntug txiav. Los ntawm cov txheej txheem ESC, lub cuab yeej ntug lub zog tuaj yeem txhim kho, lub xeev kev ntxhov siab saum npoo tau txhim kho, tus nqi ntawm qhov roughness yog txo, thiab cov cuab yeej siv tau ntev yog 1 ~ 4 zaug.

Tuam Tshoj cov roj drilling txhua xyoo thiab kev tsim cov yeeb nkab steel siv ntau tshaj 800,000 tons, kev ua cov roj av steel yeeb nkab yuav tsum tau siv ntau cov threaded hniav (ib puas txhiab daim / xyoo), yog li kev siv ESC thev naus laus zis los txhim kho kev lag luam. zoo thiab durability ntawm threaded hniav muaj txiaj ntsim kev lag luam tseem ceeb.

1. Cov yam ntxwv ntawm 1 Thread blades Daim ntawv no yog ib yam ntawm peb-hnub txhuam hniav siv rau cov xov sab nraud ntawm cov roj casing, thiab cov khoom siv hniav yog YT715 cemented carbide. Nyob rau ntawm ntug txiav ntawm txhua tus hniav ntawm hniav, 11 yam ntxwv ntsiab lus ntawm A ~ q raug xaiv, nyob rau hauv lub H point sawv cev rau lub ntsis ntawm cov hniav, cov A thiab Q cov ntsiab lus sawv cev ntawm ntug ntawm lub hauv paus, thiab cov D thiab L cov ntsiab lus sawv cev. sab ntawm ntug. Ntawm qhov kev nthuav dav siab, cov hniav ntawm ntug (piv txwv li kev sib tshuam ntawm lub hauv ntej thiab lub ntsej muag tom qab) tsis yog ib txoj kab yooj yim, tab sis ib qho nyuaj.

Lub sharpness ntawm ntug yog qhia los ntawm lub vojvoog re. Cov hniav yog machined los ua ib tug ntse ntuj ntug, raws li qhia nyob rau hauv daim duab .lub vojvoog ntawm lub ntug ntawm cov hniav zoo li tsis zoo li (re = 0.002 ~ 0.018mm).

Txhawm rau txhim kho qhov kev ntseeg siab thiab ruaj khov ntawm cov cuab yeej txiav, qhov tseeb honing ntawm ntug los ntawm ESC thev naus laus zis tuaj yeem ua rau lub zog ntawm ntug (nce re), txo tus nqi ntawm qhov roughness (ra

2. ESC thev naus laus zis thiab kev vibration honing txoj kev ESC (Edge thiab nto hardening kev kho mob) txheej txheem raws li lub hauv paus ntsiab lus yuav muab faib ua txhua yam, tshuaj, electrochemical, abrasive, thermal ua, electromagnetic thiab lwm yam kev, xws li txhuam tshuab honing txoj kev, vibration. abrasive honing method, xuab zeb blasting li txoj kev, high-speed particle bombardment method.

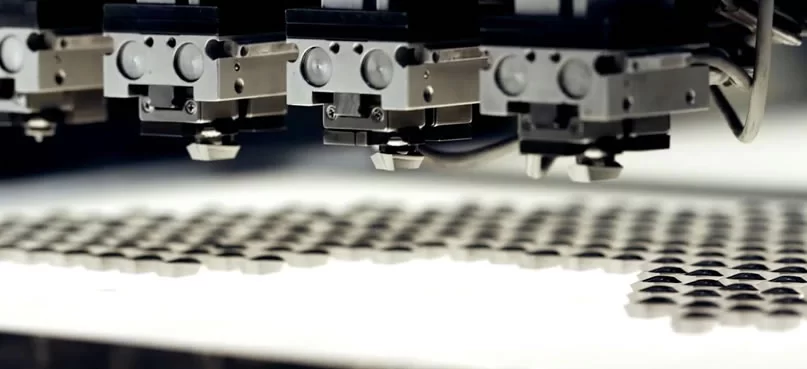

Nyob rau hauv cov ntaub ntawv no, kev co abrasive honing txoj kev yog siv los ntxiv dag zog rau lub ntug nto ntawm xov hniav, uas yog yus muaj los ntawm tsawg peev thiab tus nqi qis, thiab yuav ua tau zoo txo los yog tshem tawm cov residual kev nyuaj siab ntawm cov hniav nto, yog li ua rau lub durability ntawm cov khoom. hniav. Cov tsoos vibration honing tshuab yog tsim los ntawm vibrating mechanism (lub cev muaj zog, cam, caij nplooj ntoos hlav, thiab lwm yam) thiab worktable, abrasive siv sic los yog alumina hais, hniav thiab abrasive nyob rau hauv lub thawv ntawm lub workbench, los ntawm cov hniav thiab abrasive kev sib txhuam, muaj feem xyuam rau ua. ntug passivation. Txawm li cas los xij, nws yog ib qho nyuaj los xyuas kom meej lub vojvoog ntawm lub txiav ntug, lub vojvoog yuam kev ntawm cov hniav saum toj kawg nkaus thiab cov hauv paus hniav yog 0.02 ~ 0.09 hli, uas cuam tshuam rau kev ua haujlwm zoo thiab lub neej zoo ntawm cov hniav threaded.

Nyob rau hauv daim ntawv no, ib tug tshiab hom ntawm mechanical vibration honing txoj kev yog siv los hloov cov tsoos cam thiab lub cev muaj zog mechanism nrog ib tug tshiab hom kev co lub cev muaj zog, lub abrasive yog ib tug sib tov ntawm Emery thiab boron carbide, thiab cov txheeb ze zog ntawm cov hniav thiab cov abrasive yog txhim kho los ntawm kev siv cov tshiab fixture, kom cov hniav saum toj kawg nkaus thiab cov ntug vojvoog ntawm qhov yuam kev yog tswj nyob rau hauv 0.01mm, yog li txhim kho cov xov ua pass tus nqi thiab cov hniav zoo lub neej.